(403) 852-7589

CASE STUDIES

The application of the OXOCRETE system has had extraordinary results rehabilitating substrates at significant depths in concrete, masonry, stone and calcareous-based materials. Check out a few case studies to learn more about OXOCRETE and its various applications.

OXOCRETE is an all-encompassing solution to concrete degradation. From pH restoration to increased flexural and compressive strength, OXOCRETE can do it all. With over 25 years of proven projects and analytical data, it offers a solution to deterioration and degradation for both new and aged concrete.

OXOCRETE has been proven to:

- Restore pH to better than new levels

- Increase compressive strength

- Increase flexural capacity

- Reduce electrolytic activity

- Resist acids and chemicals

- Resist abrasion

- Exfoliate salt and other damaging materials from concrete

- Enhance concretes resistance to the effects of freeze-thaw and,

- Increase depth of penetration into the concrete matrix.

Case Studies

St. Paul's Espiscopal Church, Key West, Florida - 1992

Slated to be condemned, this churches foundation was in serious disrepair. OXOCRETE was applied to the foundation to restore its pH levels, and increase the concrete strength. Overall, the churches foundation was restored.

Overview

In 1992 the St. Paul’s Episcopal Church underwent a restoration project that utilized OXOCRETE to preserve the church’s historic stance and maintain its integrity. At the time of the project, the structure and its historical architecture was over 85 years old.

St. Paul’s Episcopal Church is located in Key West, Florida, a coastal environment with high humidity. The geographical location can cause greater susceptibility to degradation due to moisture as well as salt content from oceanic tides and winds.

Geographic Considerations

St. Paul’s Episcopal Church is located in Key West, Florida, a coastal environment with high humidity. The geographical location can cause greater susceptibility to degradation due to moisture as well as salt content from oceanic tides and winds.

Unique Conditions

The St. Paul’s Episcopal Church was constructed using a cast in place concrete construction consisting of beach sand and saltwater limestone aggregate. The added salinity of the mixture and ultraviolet exposure accelerated the structure’s oxidation-driven degradation, in addition to the moisture and salt content of the natural environment.

Objectives

Objectives for the St. Paul’s Episcopal Church:

- To preserve existing historical architecture; and

- To increase and restore the building’s structural integrity.

Results and Applicability

Samples were cored before and after the application of OXOCRETE for empirical data, which resulted in increased compressive strength from:

- 650psi to 1440 psi; and,

- 850psi to 2520psi.

The data collected from this project demonstrate OXOCRETE’s ability to restore aged concrete in environments susceptible to moisture, humidity, and ultraviolet exposure.

Seawalk Pointe, Hallandale, Florida - 1994

During construction, the concrete that was poured was below the required design strength. Faced with having to demolish and repour, OXOCRETE was a perfect alternative - the application increased the hardness of the concrete from 3000 psi to 4242 psi - a 41% increase!

Overview

During construction of Seawalk Pointe, a residential condominium located in Hallandale, Florida, the cast in place floor on the second story was poured below the required design strength. As such, OXOCRETE was utilized to increase the strength to its required rating for over 2,000 square feet of concrete flooring.

Geographic Considerations

This residence is located in Hallandale, Florida, a coastal environment with high humidity. The geographical location can cause greater susceptibility to degradation due to moisture as well as salt content from oceanic tides and winds.

Unique Conditions

This project involved freshly poured concrete that had not yet been in service or experienced degrading wear.

Objectives

Objectives for the Seawalk Pointe condominium included:

To raise the concrete from its current compressive strength rating of 3000psi to the minimum required rating of 4000psi.To preserve existing historical architecture; and

Results and Applicability

After cleaning, OXOCRETE was applied 30 days into the concrete’s curing cycle. Cores were extracted from the flooring 14 days after OXOCRETE was applied, achieving an average compressive strength rating of 3619psi across 4 specimens. To increase the compressive strength even more, the concrete flooring was surface prepped through acid etching to allow higher permeability with a second coat of OXOCRETE.

After one coat of OXOCRETE, tested cores increased from 3000psi to an average of 3619psi; and,650psi to 1440 psi; and,

After acid etching and a second coat of OXOCRETE, tested cores increased from an average of 3619psi to 4242psi.

The data collected from this project showcases OXOCRETE’s performance on new concrete applications. It demonstrates OXOCRETE as a suitable and cost-effective alternative to demolition, removal, and replacement.

Tell us About Your Concrete

OXOCRETE is proven to extend the life of concrete by 25 years + based on these case studies. And we can save you thousands of dollars by avoiding demolishing, forming and pouring of new concrete. Book a phone call and lets talk about restoring your concrete.

Pumpkin Cay, Ocean Reef, Florida - 2018

Concrete in the residences of Pumpkin Cay were exceedingly thick - 22 - 24". Oxocrete treatment was nonetheless effective in penetrating the concrete and exfoliating the acids ands salts which were the main cause of spalling and oxidation. pH levels were restored and further degradation was halted. Core samples show how well the product penetrated the concrete.

Overview

The residences at Pumpkin Cay were exhibiting signs of concrete failure, including spalling, chloride infiltration and permeation, decreased pH levels, as well as oxidation of embedded reinforcing steel.

Geographic Considerations

This residence is located in Pumpkin Cay, Florida, a coastal environment with high humidity. The geographical location can cause greater susceptibility to degradation due to moisture as well as salt content from oceanic tides and winds.

Unique Conditions

This project involved treating concrete that was exceedingly thick, approximately 22-24”, whereas typical concrete has an average thickness of 4-8”.

Objectives

Objectives for Pumpkin Kaye included:

- To restore and preserve existing concrete grades beams; and,

- To test OXOCRETE’s penetration on slabs with high thickness.

Results and Applicability

The Pumpkin Cay project involved testing cores for compressive strength, pH changes, as well as tests for oxidation and rusting.

- As of October 2018, the cored specimen demonstrated an increase in Compressive Strength from a range of 2200-2800psi to 4000psi and greater.

- The pH has been restored to like-new conditions; and,

- The once-observed spalling has since been terminated.

The value of the OXOCRETE process is strengthened through its non-destructive nature and ability to restore concrete degradation from the inside out.

Testimonial from Robert E. Samra, PE, Consulting Engineers, Letter of Endorsement, September 3, 1997

Ask us and we can provide testimonial letters from certified engineers. We take our business serious, all of our work comes with before and after testing to verify results.

Siesta Breakers, Sarasota, Florida - 1995

Due to its location on the coast, this condominium complex experienced degradation and spalling caused by high levels of humidity and salt related oxidation. OXOCRETE was used over replacing approx. 23,000 sqft of concrete balconies. As of 2021, there have been no traces of recurring oxidation of the reinforced steel or spalling of the concrete.

Overview

Siesta Breakers is a condominium complex adjacent to the Gulf of Mexico, consisting of two

six-story structures with cantilevered concrete slab balconies. Inspections of the balconies

determined the need to repair, restore or replace approximately 23,000 square feet of

concrete due to oxidative deterioration of reinforcing rebar and saltwater intrusion.

Geographic Considerations

This residence is located in Sarasota, Florida, a coastal environment with high humidity. The

geographical location can cause greater susceptibility to degradation due to moisture as

well as salt content from oceanic tides and winds.

Unique Conditions

This project involved freshly poured concrete that had not yet been in service or experienced degrading wear.

Objectives

Objectives for the Siesta Breakers Condominium included:

- To expel impurities from the concrete matrix;

- To restore alkalinity; and,

- Protect against oxidation of reinforcements.

Results and Applicability

The degraded balconies were treated with OXOCRETE, with no known further oxidation of the reinforcing steel or spalling of the concrete as of 2021.

- Restored pH levels to like-new conditions;

- Expulsed salts from the concrete matrix; and,

- Protected against further oxidation.

The restored pH, expulsion of contaminations and protection against oxidation has been maintained over time and showcases OXOCRETE’s applicability in humid, salt-rich

environments as well as traffic-bearing surfaces.

Key Benefits

Stops Further Rusting of Rebar

Enhances Freeze Thaw

Cycle Performance

Enhances Flexural Capacity

Increases PSI of Concrete

Increases Abrasion Resistance

Restores ph Levels to New Status

Mulberry Phosphates Fertilizer Plant, Mulberry, Florida - 1994

Between the geographical location next to salt water, along with the plants heavy usage of sulphuric acid, this plant experienced accelerated degradation of its concrete systems. All areas that were treated with Oxocrete remained intact until the plant was shut down in 2000.

Overview

Mulberry Phosphates was an industrial processing facility open until the year 2000, specializing in manufacturing fertilizer products for consumer and industrial use. The process utilized 98.3% sulfuric acid to breakdown mined phosphates, leading to high degradation of the plant’s concrete systems and infrastructure.

Geographic Considerations

This processing plant is located in Mulberry, Florida, a coastal environment with high humidity. The geographical location can cause greater susceptibility to degradation due to moisture as well as salt content from oceanic tides and winds.

Unique Conditions

The sulfuric acid utilized in Mulberry Phosphate’s manufacturing processes led to accelerated destruction of their concrete systems due to the corrosive and destructive nature of the acidic compounds on the alkaline-based concrete. The surfaces of cast in place concrete components were highly deteriorated and pitting.

Objectives

Objectives for the Mulberry Phosphates plant included:

- To restore pH and strength of the deteriorated concrete systems; and,

- To demonstrate applicability of OXOCRETE in harshly acidic environments.

Results and Applicability

Various components of the processing plant were piloted with OXOCRETE, including a pump pad and supporting concrete infrastructure. The pump pad had deteriorated to a negligible level and was restored to a compressive strength of 2020psi, consistent up to 3 inches deep into the concrete matrix. The concrete infrastructure demonstrated compressive strength improvements in the concrete matrix from 3992psi to 5921psi, as well as penetration improvements from 2.5”

to 5.5”.

The Mulberry Phosphates project resulted in:

- Full pH restoration to like-new conditions.

- Increase in compressive strength; and,

- Increase in penetration depth.

The increase in pH, strength, and resistance to acidic processes demonstrated OXOCRETE’s performance in harsh operational environments. The areas treated with OXOCRETE remained intact until plant shutdown in the year 2000.

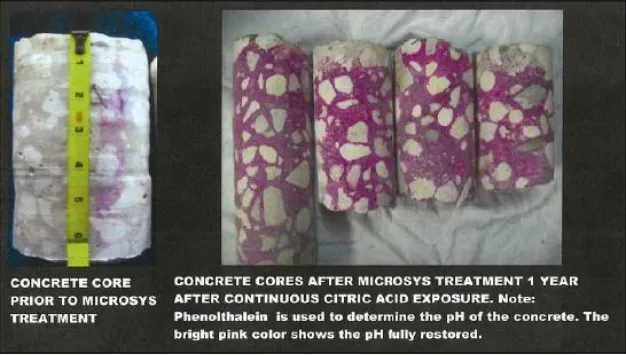

Tropicana Processing Plant, Bradenton, Florida - 2009

Another great example of how well Oxocrete preforms in harsh environments. The Tropicana processing plant experienced frequent exposure to acidic liquids. In addition to humidity, the concrete systems had undergone moderate to heavy aggregate loss and was at risk to permanent closure if these elements were not neutralized. Oxocrete proved to be an ideal solution as it made the concrete non porous and increased its flexural strength while raising the ph levels to new status, halting further degradation.

Overview

The Tropicana Processing Plant located in Bradenton, Florida had extremely high exposure to acidic materials do the nature of facility operations and fruit packaging. Specifically, the area below the plant’s Transfer Tables exhibited significant surface deterioration due to the porosity of the concrete and its allowance of the acidic liquids and vapours to penetrate through to the concrete matrix.

Geographic Considerations

This processing plant is located in Bradenton, Florida, a coastal environment with high humidity. The geographical location can cause greater susceptibility to degradation due to moisture as well as salt content from oceanic tides and winds.

Unique Conditions

The consistent and repetitive exposure to citric acid from their processing operations led to concrete aggregate loss. In addition, various repair and restoration attempts were made in previous years including pours and overlays with varying surface conditions.

Objectives

Objectives for the Tropicana processing plant:

- To restore pH levels of the concrete; and,

- To protect the concrete from further deterioration or acidic degradation.

Results and Applicability

After one year of OXOCRETE treatment and continued exposure to citric acid environments, the concrete demonstrated full pH restoration throughout the concrete matrix.

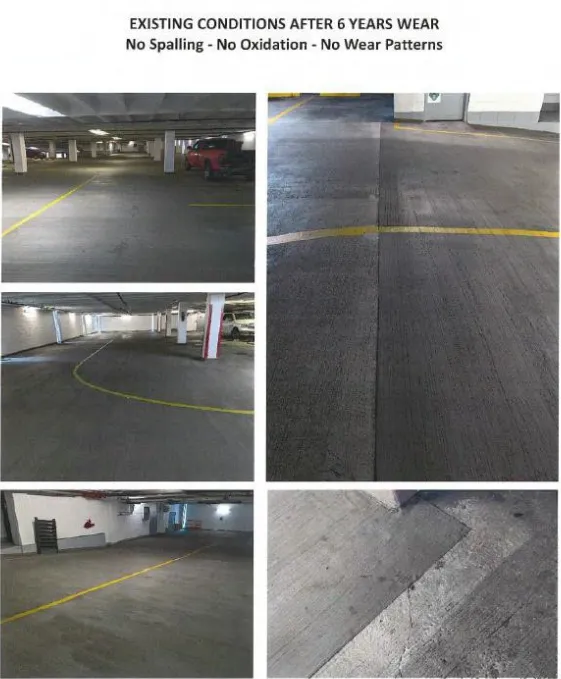

Wells Fargo Advisors Building Parking, Sarasota, Florida - 2015

Another great example of how well OXOCRETE preforms in harsh environments. The Tropicana processing plant experienced frequent exposure to acidic liquids. In addition to humidity, the concrete systems had undergone moderate to heavy aggregate loss and was at risk to permanent closure if these elements were not neutralized. OXOCRETE proved to be an ideal solution as it made the concrete non porous and increased its flexural strength while raising the ph levels to new status, halting further degradation.

Overview

The OXOCRETE system was utilized in 2015 for the Wells Fargo Advisors Building, due to heavy wear and deterioration caused by traffic patterns. The OXOCRETE system was applied to the prepared substrate prior to resurfacing, which has shown minimal signs of wear as of March 2021.

Geographic Considerations

This processing plant is located in Sarasota, Florida, a coastal environment with high humidity. The geographical location can cause greater susceptibility to degradation due to moisture as well as salt content from oceanic tides and winds.

Unique Conditions

This parking structure has significant traffic daily which contributes to the overall wear and degradation of the structure and parking surface.

Objectives

Objectives for the Wells Fargo Advisors Building Parking:

- To protect the new substrate from wear and deterioration; and,

- To reduce electrolytic activity within the concrete matrix.

Results and Applicability

For the portion of the parking surface applied with OXOCRETE, no visible wear or deterioration has been observed as of March 2021 (6-years post-application). It is visibly consistent throughout, uncompromised with no evidence of oxidation within the concrete as confirmed via Proceq Profometer Testing.

- Full pH restoration to like-new conditions.

- Increase in compressive strength; and,

- Increase in penetration depth.

Work With Us

Solidform Concrete Solutions provides professional solutions for protecting and restoring your concrete back to new status. Get in touch with us to talk about your next project.

Included With Every Job

Below are some additional services that are included with every job

Before and After Testing

With every job, we provide complimentary before and after testing to verify the results of treating concrete with OXOCRETE. Testing will show a dramatic improvement in pH levels, as well as concrete strength. In addition. For structural concrete, we also provide core samples that are tested in a certified lab and approved by structural engineers.

Online Client Profile

At the finish of every job, you will be given login information to access everything related to the job including quotes, invoices, warranty info, before and after testing, core sample results, before pictures, after pictures, videos, etc. Everything in one place for easy reference.

10 Year Warranty

All concrete treated with OXOCRETE comes with an Industry leading 10 Year Warranty. Longer warranties are available for purchase including 15, 20 and 25 year warranties. We stand behind our work and guarantee results.

(403)852-7589

3900, 350 – 7th Avenue SW,

Calgary AB T2P 3N9

Copyright Solidform Concrete Solutions 2022 -- All Rights Reserved

We’re on a mission to create sustainability in the concrete industry. By offering an alternative to demolishing concrete we help keep our planet just a little greener.