(403) 852-7589

Resources

Here you can find answers to just about any question regarding OXOCRETE and its application. As well, there are downloadable documents you can print for reference.

Get on a phone call with use for an in-depth discussion about your concrete needs.

Frequently Asked Questions

How does OXOCRETE work?

Concrete poured 50-70 years ago, and in some instances earlier, have experienced serious carbonation and electrolytic activity resulting in embedded steel rusting and concrete structures failing.

OXOCRETE is the worlds most advanced system for rehabilitating concrete. This safe and environmentally friendly product, which has been under development, testing, improvement and usage since 1992, actually changes the concrete matrix to make it stronger, harder, virtually impermeable, all while reinstating the pH which inhibits corrosion reinforcing steel, preventing ‘Carbonization’ (deterioration of the concrete matrix through the absorption of atmospheric CO2) and increasing the flexural strength. So, for the affected depth of penetration, OXOCRETE essentially turns your concrete into rock. These results are not attainable through any other technology in the world, and greatly increase the longevity of concrete assets. With much of the worlds older concrete requiring critical repairs or replacement, OXOCRETE offers a cost-effective solution to protect and rehabilitate valuable concrete

How does OXOCRETE improve/enhance the concrete?

Through extensive certified laboratory testing since 1992 the following consistent results have been noted:

· restored pH to better than new levels

· increased compressive strengths within the matrix up to 10” deep

· increased flexural capacity

· reduction and elimination of electrolytic activity

· acid and chemical resistance

· abrasion resistance

· salt and other harmful material exfoliation from treated substrates

· freeze-thaw effects eliminated.

How does OXOCRETE affect the pH of the concrete?

Due to the chemical composition of the OXOCRETE CPR-2 product and the ability of the product to penetrate deep within the concrete matrix, the alkaline nature of the product will restore the pH of the concrete matrix to that of new concrete

How does OXOCRETE mitigate/prevent corrosion?

Due to the chemical composition of the OXOCRETE CPR-2 product and the ability of the product to penetrate deep within the concrete matrix, the alkaline nature of the product will restore the pH of the concrete matrix to that of new concrete, this in turn will halt further rusting of embedded steel. OXOCRETE will also effectively seal the concrete from intrusion of any harmful substances. During the application process OXOCRETE will exfoliate salts and acids out of the concrete matrix as it penetrates.

How long has the product been in use?

The fist project started in 1992 and has been successfully implemented on many various projects.

Are the products Hazardous?

CPR-1 is completely harmless and is to be treated in the same way as potable water. CPR-2 is a chemically formulated product which has been certified as “Generally Regarded As Safe or GRAS by the US FDA. Standard safety protocols to be followed when handling products. CPR-2 is considered environmentally safe and poses no harm to humans or fauna and flora. Excessive amounts maybe fatal to aquatic life. How much and at what concentration CPR-GREEN-CLEAN is an environmentally safe cleaning product, Non-Toxic, Non-Flammable, Odor Free, Effective with hard water, Non-Corrosive, Non-Staining, Non-Irritating, Water Based, No Masking agents, No Anti Foamers, No Solvents, No Phosphates, No Animal Fats, No Soaps. All ingredients in CPR-GREEN-CLEAN fall under the GRAS certification

Does OXOCRETE work on all types of concrete?

OXOCRETE will work on all kinds of concrete. However, if concrete has any protective coatings on the surface, that coating will need to be removed prior to application. As well, in some cases, OXOCRETE may not work as well if there have been significant amounts of admixes added when it was poured. Our applicators will test the concrete first to ensure that OXOCRETE application will be successful.

Another important note, OXOCRETE will not be applicable if the concrete is too far gone. At the initial inspection, our trained applicators will be able to properly diagnose whether OXOCRETE will be a viable solution.

Where can OXOCRETE be used?

OXOCRETE works best on raw concrete - where the surface of the concrete has no sprays, coatings, paint, etc. on it. In these cases where there is a coating, the coating must be removed via pressure washing or shot blasting to ensure proper absorption of the product.

What will OXOCRETE do to my concrete?

Through extensive certified laboratory testing since 1992 the following consistent results have been noted:

1) restored pH to better than new levels

2) increased compressive strengths within the matrix up to 10” deep

3) increased flexural capacity

4) reduction and elimination of electrolytic activity

5) acid and chemical resistance

6) abrasion resistance

7) salt and other harmful material exfoliation from treated substrates

8) freeze-thaw effects eliminated.

Can OXOCRETE be used on new concrete?

Yes! In one case study, the wrong concrete was ordered which did not have the proper strength. Thanks to OXOXRETE, the concrete was treated (after 14 days of curing) and the strength was increased significantly to meet the designs necessary standards.

How long does it take to apply OXOCRETE?

Depending on the thickness of the concrete, it may take a minimum of 4 coats of both CPR1 and CPR 2. In applying CPR1, we will mist on the product until saturation has been achieved. The product absorbs quite quickly, so typically once the first coat has been applied, the concrete is most often ready right away for the second coat. Depending on the thickness of the concrete, it can take between 4 - 12 coats to achieve saturation. This same same process is true for the application of CPR2.

What conditions are required for application? (Environment, weather, season, etc.)

OXOCRETE products can only be applied to a clean concrete surface and cannot be applied in extremely windy conditions or rain. The concrete surface temperature must be above 7deg C or 45 deg F. OXOCRETE products are not allowed to freeze at any time

What does the preparation process entail? (Cleaning, drying, coring samples if desired).

An ideal preparation process would be an Applicator entering into a Pre-Construction Agreement with the client where the following processes will be applied

1. Concrete cleaning and preparation, to determine the cleaning process required

2. Pre-application concrete core samples to establish a baseline

3. Application of CPR-1 and CPR-2 to determine absorption rates, final cleanup

4. Post application concrete cores samples at 30, 60 and 120 days to establish application results against the baseline samples

How does OXOCRETE compare to other concrete admixes that strengthen concrete?

ASTM C494 specifies the requirements for 7 chemical admixture types:

Type A: Water-reducing admixtures ·

Type B: Retarding admixtures ·

Type C: Accelerating admixtures ·

Type D: Water-reducing and retarding admixtures ·

Type E: Water-reducing and accelerating admixtures ·

Type F: Water-reducing, high range admixtures ·

Type G: Water-reducing, high range, and retarding admixtures

Admixtures are used to improve the quality of concrete during mixing, transporting, placement and curing. Admixtures can also support the increased strength and reduce permeability of the concrete. Without additional surface hardeners and sealers applied constantly throughout the lifespan of the concrete structure, it will deteriorate and eventually fail.

OXOCRETE applied to concrete regardless of age, the concrete needs to have cured, will provide the benefits of admixtures and more, it will strengthen, increase flexural strength, reinstate pH, stop all electrolytic activity, increase abrasion resistance, seal the concrete from the effects of salts, acid and carbonation

Who can apply OXOCRETE?

Only trained and OXO certified Applicators may use the proprietary equipment and OXOCRETE products. All applicators are trained by OXO H2O Solutions and receive a certificate upon successful completion of the applicators course.

What does the training and certification process entail to apply OXOCRETE?

Training is provided by a certified OXO trainer over a two-day period where day one, the Applicators complete concrete cleaning, product application and final clean up modules, each module will have a set of questions which the Applicator will need to complete and pass. The second day will be hands on equipment training and actual product application to the satisfaction of an experienced OXO inspector. These activities need to be completed to become a OXO certified Applicator.

Can OXOCRETE be applied over existing rust and corrosion?

OXOCRETE will bond with rusted metal and halt corrosion, this is not considered a best practice repair solution. Any corroded rebar or embedded steel needs to be repaired following ASTM or ICRI or other applicable building codes, once the repairs have been completed, OXOCRETE can be applied to the repaired area and buildout of the area completed.

Can it be applied to concrete that is spalling?

It can be applied to spalling concrete, however, this is not a best practice repair procedure. Any spalling concrete or corroded rebar, or embedded steel needs to be repaired following ASTM or ICRI or other applicable building codes, once the repairs have been completed, OXOCRETE can be applied to the repaired area and buildout of the area completed.

Can it be applied to vertical surfaces?

As OXOCRETE is atomically altered and oppositely charged to concrete, the resulting misting will allow for attraction and penetration of the product on any clean concrete surface regardless of orientation

Can OXOCRETE be applied to both outdoor and indoor surfaces?

There are no limitations as to where OXOCRETE can be applied, as long as the concrete surface is clean and not below 70 C or 450 deg F at the time of application

Can it be put into the mix of new concrete?

Some testing has been done with positive results on small batches of new mix concrete, however, significant research and development would need to be conducted on large batch concrete mixes before any marketing can take place

How long does new concrete need to cure before the product can be applied?

It is recommended to wait at least 10 days after initial curing of 28 days before applying the OXOCRETE products

Will OXOCRETE affect the colour of my concrete or stain?

OXOCRETE is hazy or clean in color and penetrates below the surface of the concrete and will not affect existing concrete or stains

Can I apply coatings or sealers such as bonding agents, paint, epoxy, urethane etc. after treatment of OXOCRETE?

OXOCRETE when applied as per the training and SOP will leave a surface profile that is not bond breaking and will allow other sealers or products to be applied. There is no defined rule as to when products can be applied, the surface will need to be clean and dry, this may take a day or two for the concrete surface to be completely dry.

What OXOCRETE Guarantee or Warranty do you have?

OXO H2O Solutions will provide a 10-year warranty covering the properties of the product, compressive strength, flexural strength and reinstatement of the alkalinity or pH of the treated concrete only up to the depth of penetration. Solidform Concrete Solutions will warranty their workmanship for 1 year

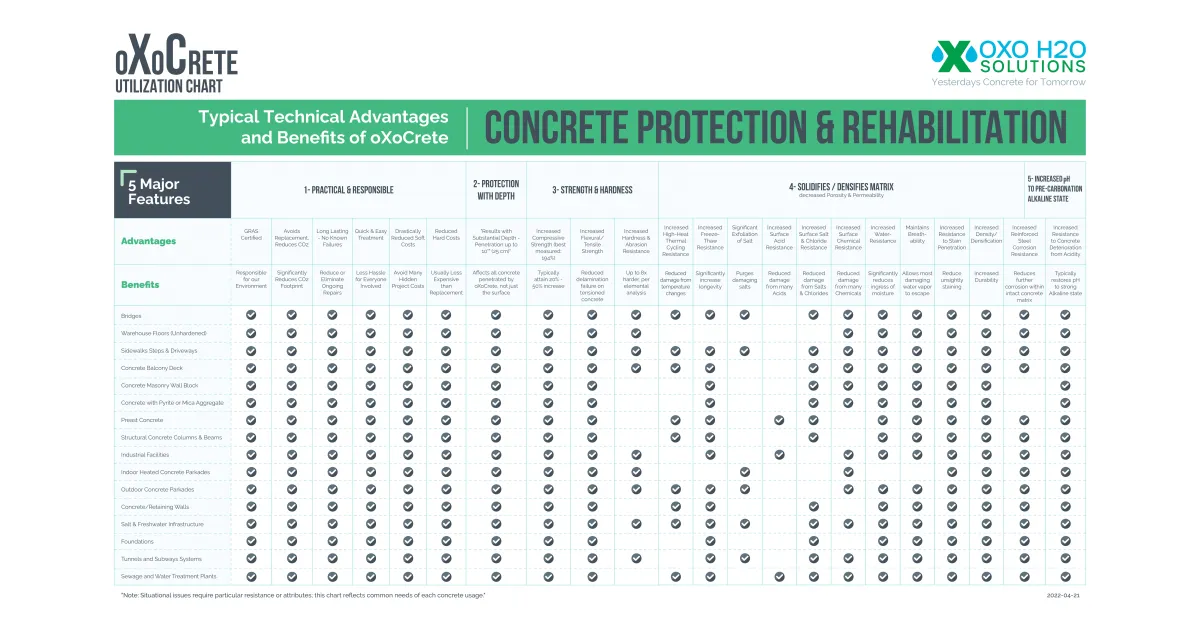

Technical Advantages of OXOCRETE chart

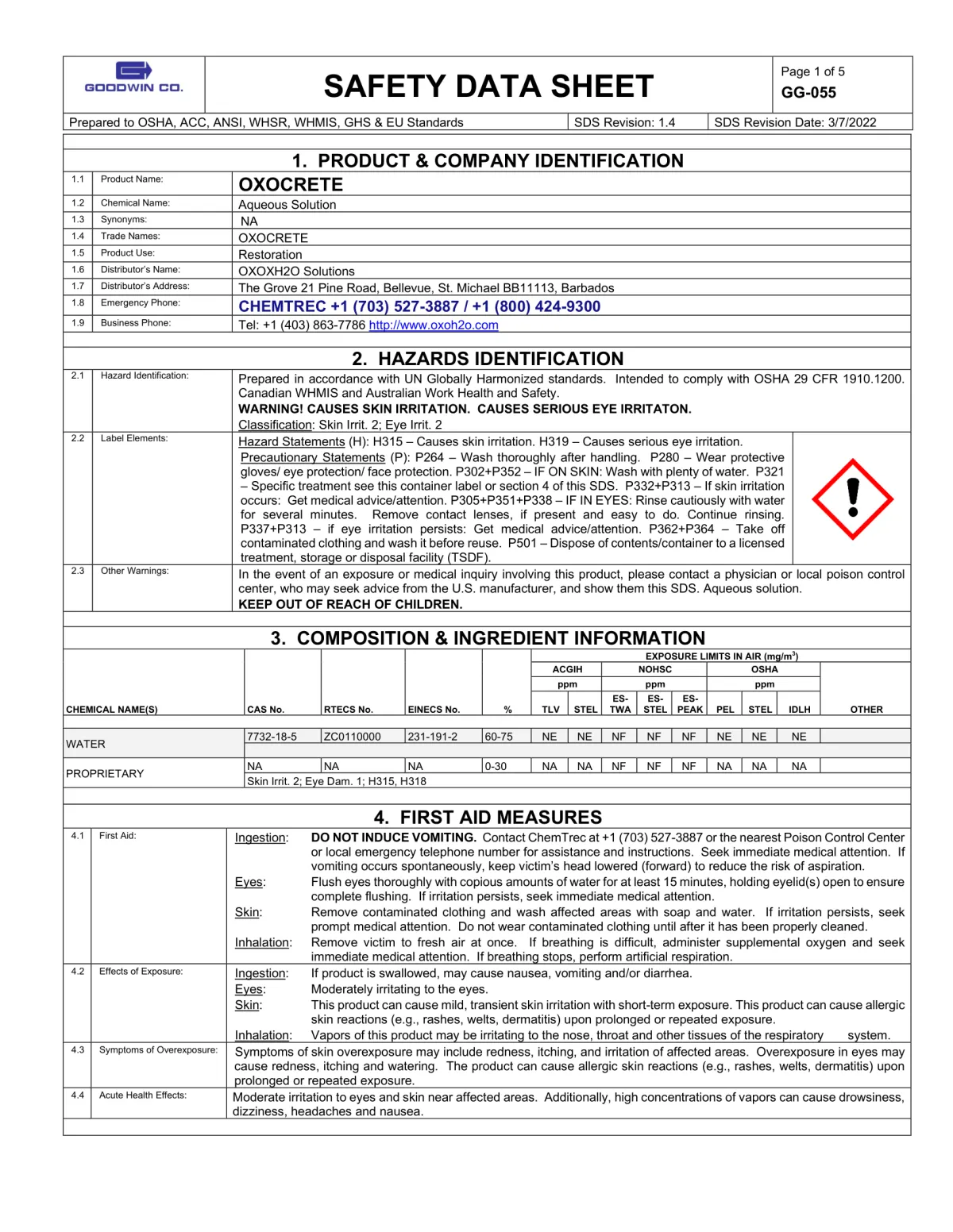

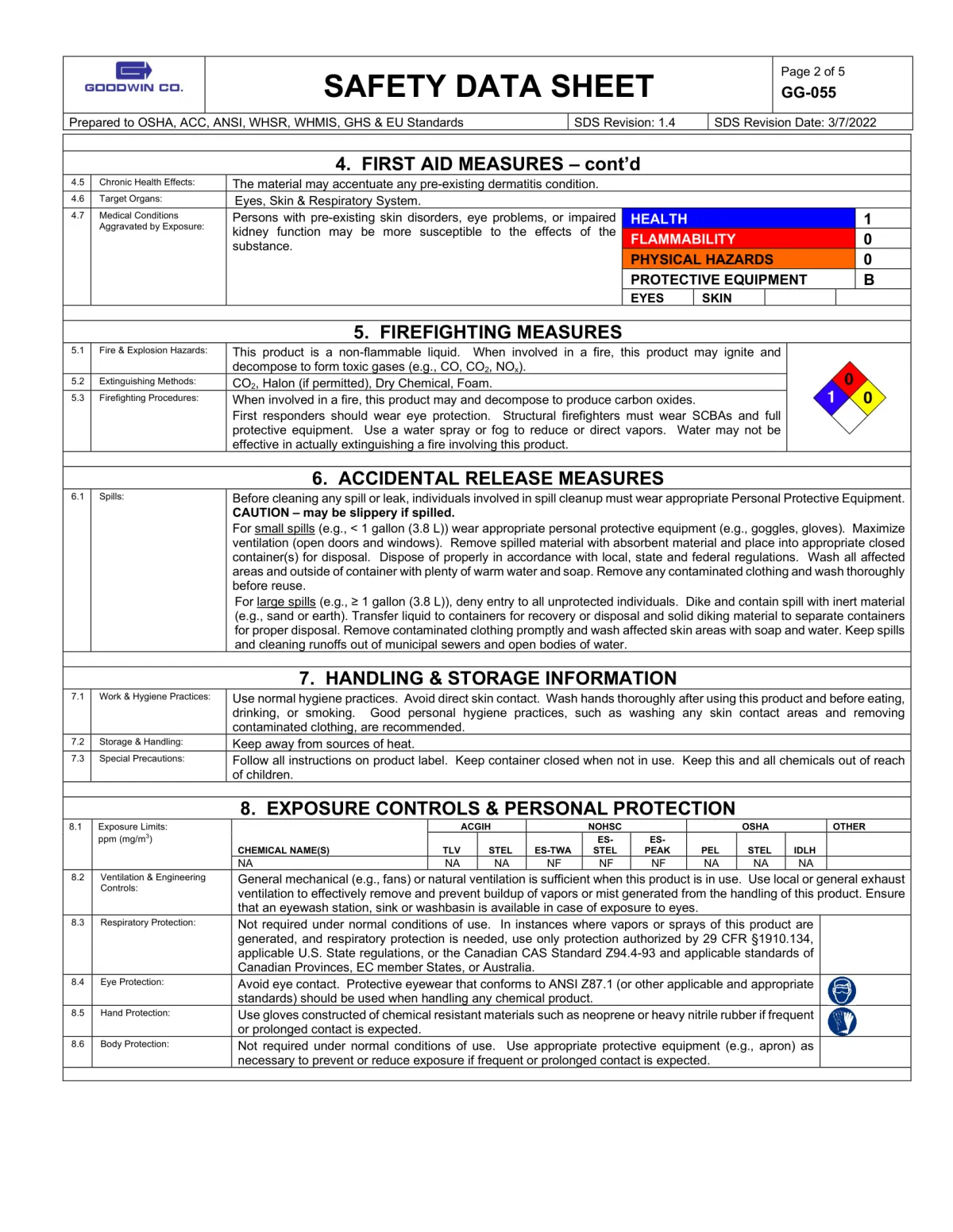

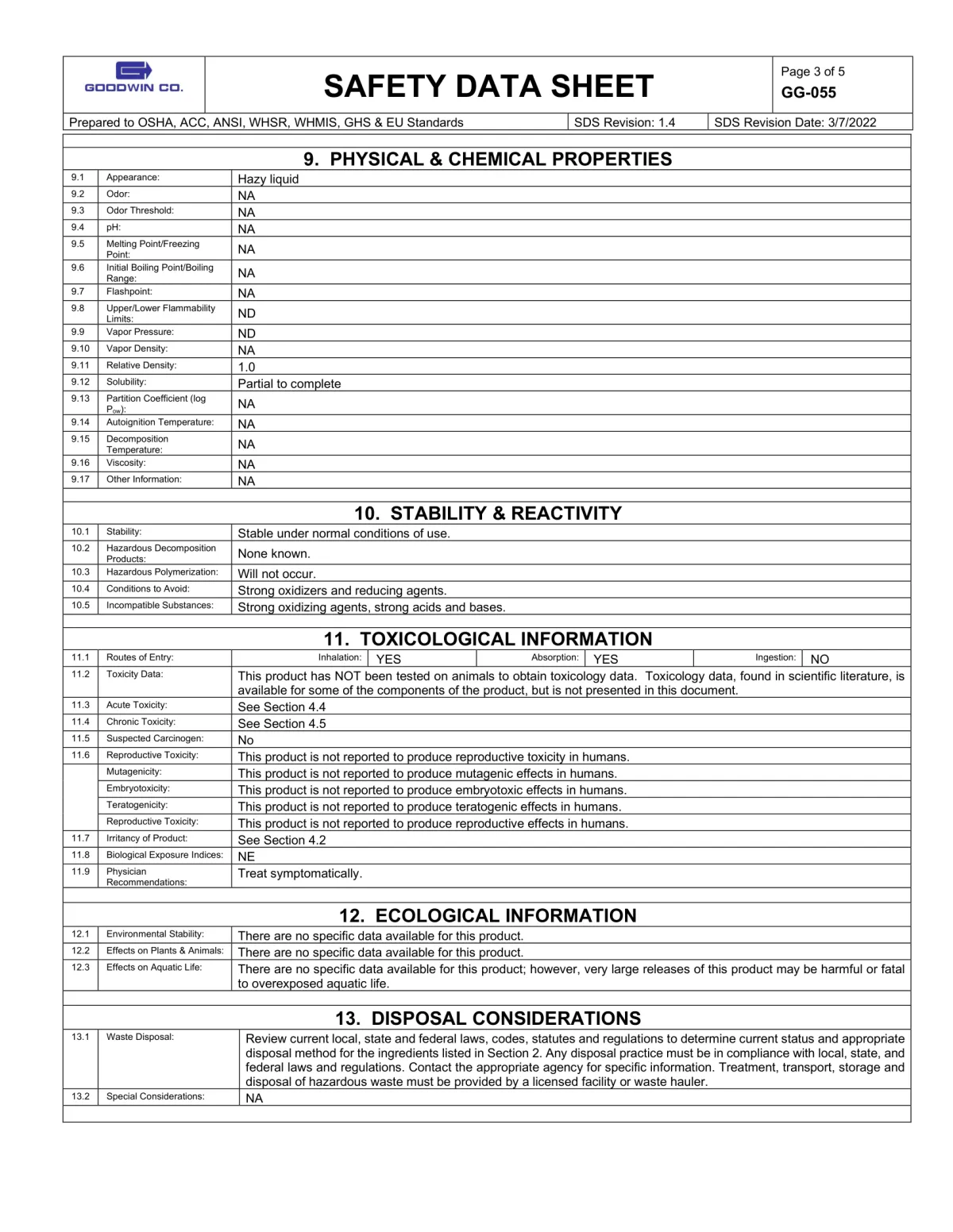

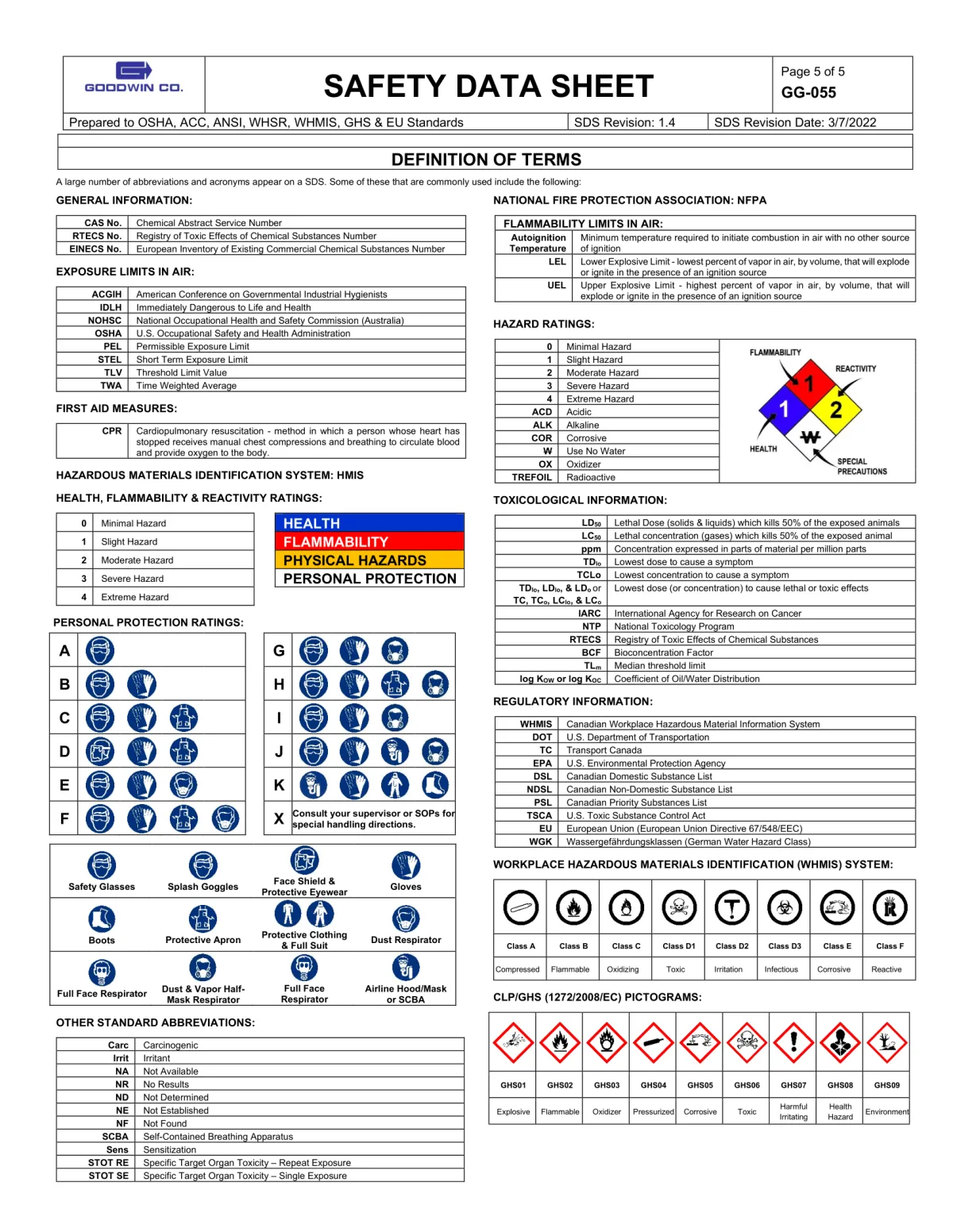

Safety Data Sheet for OXOCRETE

Videos

(403)852-7589

3900, 350 – 7th Avenue SW,

Calgary AB T2P 3N9

Copyright Solidform Concrete Solutions 2022 -- All Rights Reserved

We’re on a mission to create sustainability in the concrete industry. By offering an alternative to demolishing concrete we help keep our planet just a little greener.